Guest Blog: Assessing energy storage technologies. Should you go with the flow?

The Golden State is one of the fastest growing markets for energy storage in 2020. Driven by falling equipment costs, attractive, secure revenue streams and a host of incentives implemented at both state and federal level, more and more solar PV developers, EPCs, CCAs and utilities are looking to include energy storage in their projects. However, with a host of battery technologies to choose from, it’s no easy task to pick the right one for your California energy storage project.

Rob Brown, Invinity’s California-based Regional Director for North America, shares answers to some of the most frequently asked questions he hears and gives his view on the key areas often overlooked when specifying energy storage for solar PV sites.

“So, where does your technology differ from lithium?” It was the standard song and dance, and I knew the tune. I was on the phone with the 5th company that day that had been reading about flow technology and wanted to learn more. “How do you know flow is going to be the right fit for me?”

Flow batteries have become an increasingly popular topic in recent months. The drawbacks of lithium technology are becoming better understood, and much of the industry is looking into alternatives. What does one gain (or lose) by switching away from lithium?

Let’s talk cycles

The popularity of lithium systems (it’s been widely deployed in one form or another since the 80s) has also provided a wealth of performance data that aids in the conversation. Due to lithium’s inherent degradation characteristics, it is a technology best suited to applications with low cycle counts and less-than-complete depth of discharge. Case in point, many lithium warranties are only valid if the system is used fewer than 200 cycles per year, and only within 20%-80% state of charge. These limitations typically end up fitting lithium into applications that require short durations only a few very lucrative times per year.

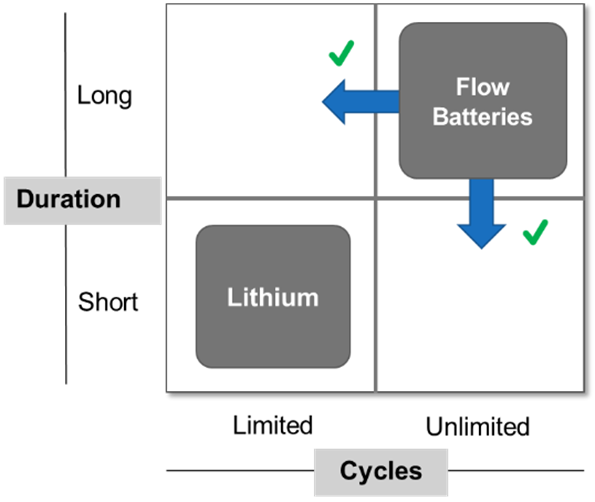

Figure 1 illustrates the differences between lithium-ion and vanadium flow battery technology and which applications they are best suited for.

‘Flow technology, on the other hand, has its strengths in the very applications where lithium struggles. With effectively no incremental cost to cycle, and the ability to perform full, 100% depth of discharge every time, flow batteries lend themselves to heavy-use applications where large amounts of energy are stored or shifted. In fact, the most popular applications for flow batteries occur where the battery is intended to cycle more than 300 times every year, for 20 years. These heavy-use situations create an environment where flow systems have a lower Total Cost of Ownership (TCO) than any other storage technology.

To illustrate the idea, lets look at a few examples:

Chemical Manufacturing in California – UPS / Backup

I once worked with a chemical manufacturer in the Bay Area that had one major complaint: their utility company was unreliable. This was before the era of PSPS events and multi-day outages, and the issue was with about a dozen micro-outages throughout the year.

On occasion, and without warning, the electric supply would drop for up to a full second. While this might not sound like a lot, that interruption would wreak havoc on the production line. Chemicals that were carefully being mixed and processed would suddenly become vats of worthless sludge. The company estimated that the micro-outages cost the company $100k-300k in lost material with each occurrence; and at $1.5M annual losses due to this problem, they were extremely interested in fixing the problem.

The solution was clearly to cycle a battery around 12 times a year for less than a minute each time. Due to the short duration, low cycling needed to address the issue, I recommended to my client a lithium system to act as an uninterruptible power supply (UPS). There’s simply no point in installing a flow battery just for UPS, whilst it’s technically capable of providing that service, lithium (or lead-acid for that matter) is the more economic choice if occasional back-up is all you are going to use it for.

Grid Stabilization in the United States – Frequency Response

With the growing popularity of renewables on the electric grid, as well as the electrification of nearly every consumer good, utility frequency is becoming more and more unstable. While the details of this phenomenon are worth a separate blog post, suffice it to say that Independent System Operators (ISOs) are under increased pressure to deliver the 60Hz we’re used to.

The solution to balancing frequency, is to add additional generation or load as required. Historically, this was accomplished with generators, but energy storage has become much more popular in recent years since a battery system acts as both a generator and a load depending on whether it is charging or discharging. When frequency is too low, the battery is called upon to discharge. When frequency is too high, the battery is told to charge. These cycles often last only a few minutes at a time, but can be constantly shifting between charge and discharge hundreds of times each day.

This application requires very short durations from the battery system, so one might think lithium is a good fit. However, these small durations often add up to more than 400 full-cycle-equivalents over the year. If the battery is going to be running nearly 24 hours per day, all year long, a more durable technology like flow might be a better fit.

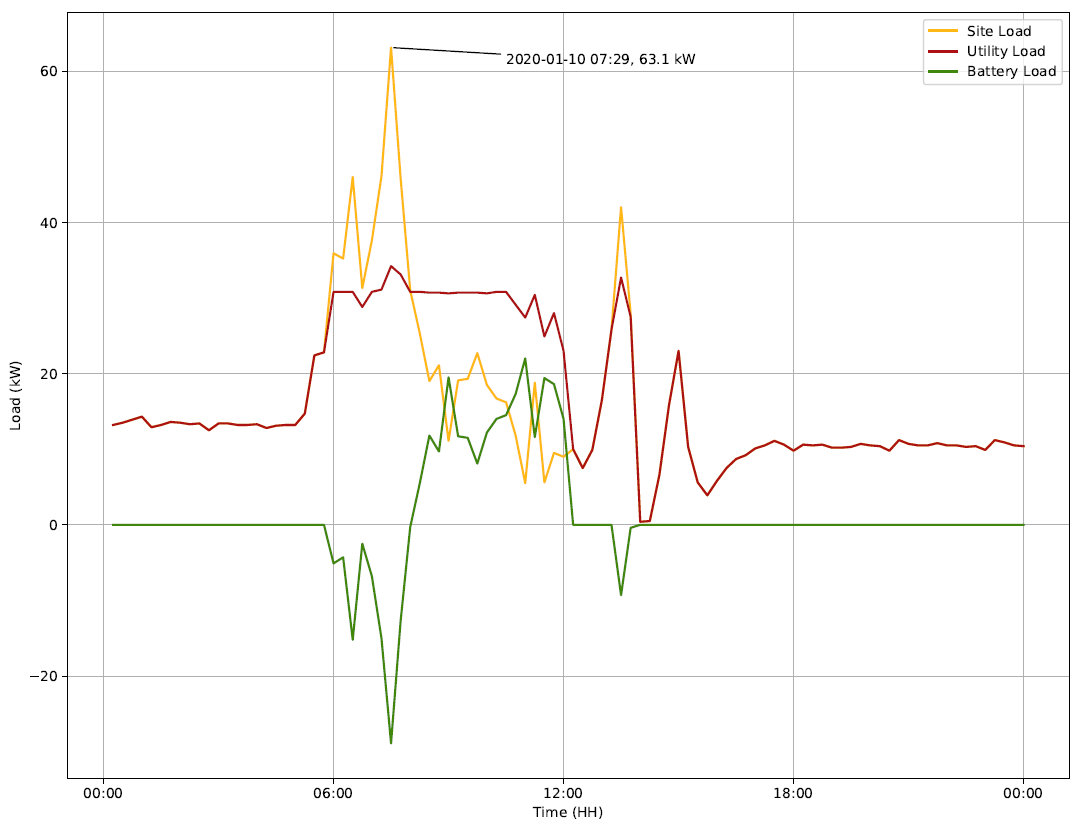

Light Industrial and California Energy Storage – Demand Shaving / Arbitrage

A few years ago, I worked with a latex manufacturer in southern California. They were frustrated by the demand charges they were seeing on the utility bills, and they wanted to save some money. My team and I analyzed their usage and recommended a solar + storage system that would shave demand and take advantage of time-of-use energy prices. The resulting battery system had a 4-hr duration and was expected to cycle about 350 times per year. Not surprisingly, we recommended a flow battery for this application. The system was installed in 2017, and has been saving the site more than they expected. In fact you can see the system in daily operation below.

Figure 2 is an actual 24-hour period showing an Invinity flow battery ‘shaving’ peak demand for an industrial site in Pomona, CA

Conclusion

No single technology can do everything for everyone. As the energy storage industry continues to evolve, it is critical for each of us to consider each technology’s strengths and match those strengths with the right applications. This post is the first of a three-part series. The next segment will cover how to size a storage system. The final of the series will cover hybrid systems, and how multiple technologies might function as a team on the same site.

Send us an email or get in touch via the contact form